Definition of COIL

(external current field source)

by hexahedral element mesh

- TOP >

- Analysis Examples by Functions (List) >

- Definition of COIL (external current field source) by hexahedral element mesh

Summary

In EMSolution, COIL can be created and defined as a hexahedral mesh. Hereafter, COIL defined by a mesh is referred to as Meshed COIL.

Explanation

Application to modelling of helical coils

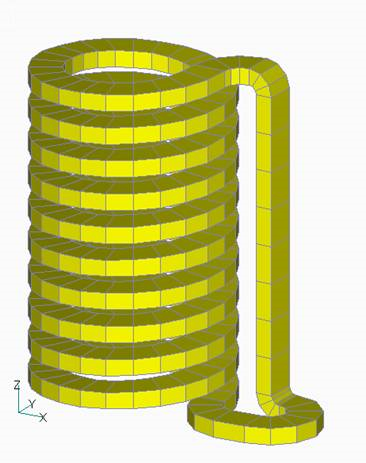

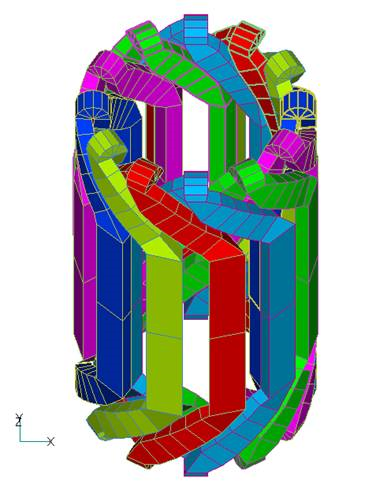

The model shown in Fig. 1 is created as follows: First, a quadrilateral coil cross-sectional shape is created. Next, it is extruded along the length of the coil to create a hexahedral element.

The cross section does not necessarily have to be rectangular and can be distorted. However, the four nodes on the bottom and top surfaces of the hexahedral element must be in one plane. If the upper and lower surfaces are not on one plane, the calculation can still be performed, but strictly speaking, current continuity may not be satisfied. The mesh defined in this way is stored in the file "COIL_geom.xxx" as an input file. The .xxx extension depends on the INPUT_MESH_FILE in "input. 10. input/output file”. If the geometry can be expressed by ARC or GCE, it is better to use them to obtain a more accurate solution since they are calculated analytically.

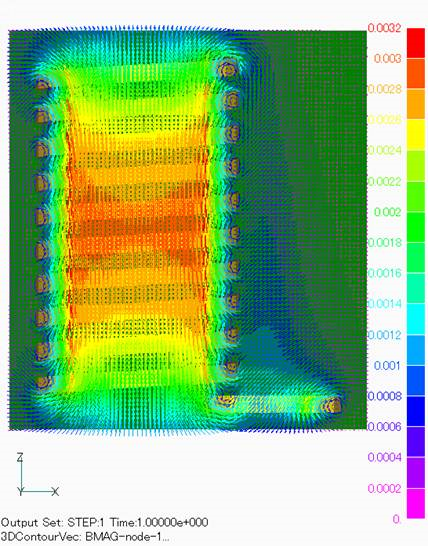

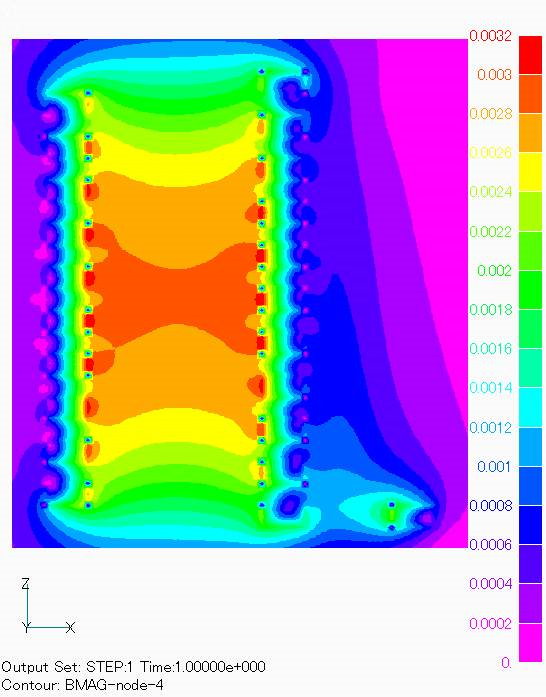

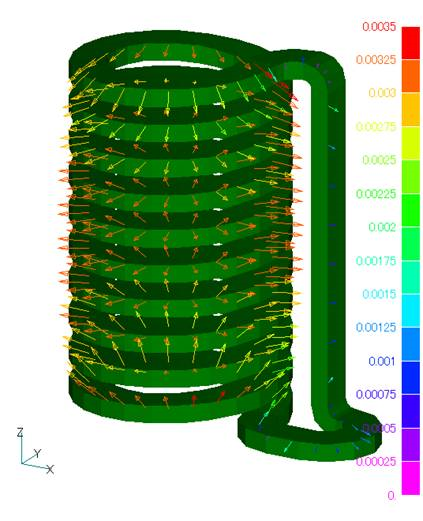

Fig.2 and 3 show the magnetic field on the center plane obtained by current integration. The definition of Meshed COIL is described in the definition of COIL as well as GCE, ARC, etc. When CALC_IND is set to 1, the inductance is calculated and included in the circuit calculation. The results of the electromagnetic force calculation for COIL are shown in Fig. 4. Although only the self-force of COIL is calculated in this calculation, electromagnetic force calculations that include the contribution of conductors and magnetic materials are also possible by combining the finite element method.

For inductance and electromagnetic force calculations, you can specify the number of Gaussian integration points in the element cross section (NX, NY) and Gaussian integration points in the current direction (NZ). Setting NZ=0 performs an adaptive calculation that automatically determines the number of integrals in the current direction. Table I shows the results of inductance calculations with these parameters. In this example, NX=NY=NZ=3 seems to be sufficient. As the number of hexahedral elements increases, the computation time increases (the computation time for inductance is proportional to the square of the number of elements). In addition, when used as a magnetic field source in a reduced potential region, integration at the boundary surface is required, which can be very time-consuming. This problem can be avoided by using the restart function. Since this calculation and inductance calculations are performed in the MAKE_SYSTEM_MATRICES process, it is possible to calculate the inductance first, and enter the inductance as a circuit constant in NETWORK or CIRCUIT and then to make calculation with the CALC_IND option set to 0. (This saves calculation time.)

Table I. Inductance Calculation

| Nx | Ny | Nz | CPU Times ( s ) | Inductance( μH ) |

| 3 | 3 | 3 | 95.3 | 7.31916 |

| 5 | 5 | 5 | 452.7 | 7.31831 |

| 7 | 7 | 7 | 1218.5 | 7.31815 |

| 3 | 3 | 0 | 240.7 | 7.31875 |

Application to rotating machine windings

The following is an example of using Meshed COIL for the stator winding of a rotating machine (permanent magnet motor).

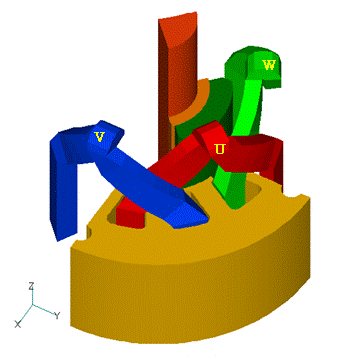

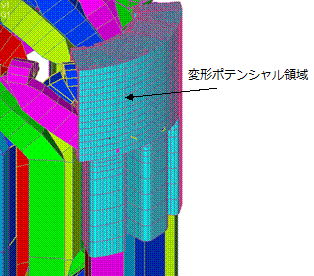

Fig. 5 shows the whole shape of the defined coil. One coil is created, rotated and copied to make 12 coils, and each phase is given a property number. Since this analysis uses top-bottom symmetry and 4-fold periodic symmetry, the integral region is defined only in the 1/8 region for the inductance calculation, and the integral region is defined separately as shown in Fig. 6. The Meshed COIL defined in this way must be defined within the reduced potential region, just like a conventional COIL. This is shown in Fig. 7. The reduced potential region is defined as the region covering the coil slot and the coil end portion.

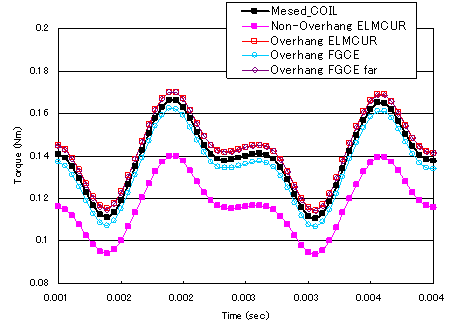

The torque waveforms analyzed by Meshed COIL are shown in Fig. 8. The results are superimposed on the results of other modeling (Fig. 11 of "Application of COIL to Motor Winding"). Note that the coil end portion shown in Fig. 5 was created virtually; in reality, it must be modeled according to the real equipment.

The rest of this page is for members only.

Analysis Examples by Functions

External current magnetic field source

- About the multi-potential method

- Definition of COIL (external current field source) by hexahedral element mesh

- Magnetic field distribution calculation in a COIL-only model

- Circuit calculation with COIL (external current field source) only

- COIL inductance and electromagnetic force calculations

- Inductance Calculation for COIL (external current magnetic field source)

- Handling of inductance in external current field source (COIL)

- About COIL Move

- Problems with external magnetic field current sources in the case of translational periodicity

- Notes on the use of GCE (rectangular current element)

©2020 Science Solutions International Laboratory, Inc.

All Rights reserved.